CerMark LMM6000 Spray Can, 340g

- LMM6000 Spray Can

- Black Laser Marking

- For Many Metals

- Contents 340 g

CerMark LMM6000, 100g

- LMM6000 Concentrate

- Black Laser Marking

- For Many Metals

- Contents 100 g

CerMark LMM6000, 250g

- LMM6000 Concentrate

- Black Laser Marking

- For Many Metals

- Contents 250 g

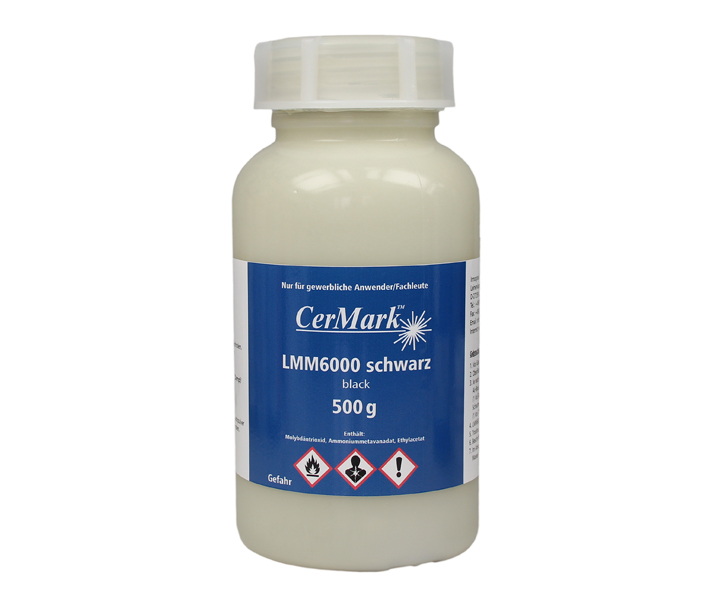

CerMark LMM6000, 500g

- LMM6000 Concentrate

- Black Laser Marking

- For Many Metals

- Contents 500 g

TherMark Spray LMM14, 170g

- LMM14 Spray Can

- Black Laser Marking

- For Many Metals

- Contents 170 g

CerMark LMM6018, 25mm x 15m

- LMM618 Metal Marking Tape

- Dry Application

- Black Laser Marking

- For Many Metals

- 25 mm x 15 m

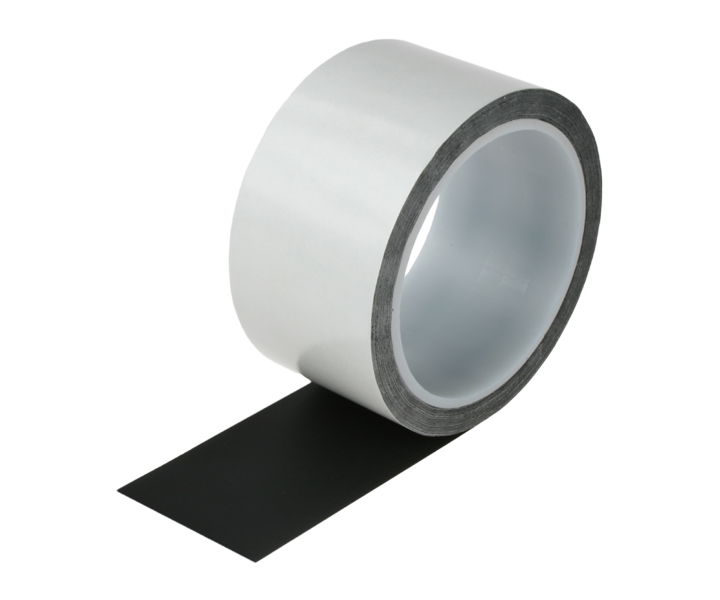

CerMark LMM6018, 50mm x 15m

- LMM6018 Metal Marking Tape

- Dry Application

- Black Laser Marking

- For Many Metals

- 50 mm x 15 m

CerMark LMC6044p Spray Can, 340g

- LMC6044p Spray Can

- Black Laser Marking

- Glass and Ceramic Marking

- Contents 340 g

CerMark LMC6062p, green, 50g

- LMC6062p

- Green Laser Marking

- Glass and Ceramic Marking

- Contents 50 g

markSolid 114 Aerosol Spray, 300ml

- markSolid 114 Spray Can

- Black Laser Marking

- For Many Metals

- Contents 300 ml

markSolid 114 Aerosol Spray, 100ml

- markSolid 114 Spray Can

- Black Laser Marking

- For Many Metals

- Contents 100 ml

markSolid 590, black 50g

- markSolid 590

- Black Laser Marking

- Glass and Ceramic Marking

- Contents 50 g

CerMark, markSolid and Spectrumark: Laser marking of Metals, Glass and Ceramics with high contrast

CerMark LMM6000, CerMark ULTRA, TherMark LMM14, markSolid and Spectrumark are leading products for the laser marking of metals, glass and ceramics. These special coatings are applied to the surface and heated by laser, creating a permanent and high-contrast marking. After engraving, the excess coating is washed off, leaving only the marking visible.

These coatings can be used for a wide range of applications. They create particularly effective and durable markings on metals such as stainless steel, aluminium, brass and copper. On glass, they create durable and high-contrast decorations.

These products offer numerous advantages. They create high-contrast markings that are easy to read. The markings are resistant to abrasion, chemicals and weathering.

The application process involves several steps. Firstly, the surface must be cleaned and dried. The coating is then applied evenly and must dry completely. The surface is then engraved with the laser, which heats the coating and creates the marking. Finally, the excess coating is washed off.