- Products

- About us

- Contact

- News

Standard Cutter 3,00x50mm

- Solid Carbide

- Standard Cutter

- 3,00 x 50 mm

- 9 available tip sizes

Standard Cutter 3,17x115mm

- Solid Carbide

- Standard Cutter

- 3,17 x 115 mm

- 9 available tip sizes

Standard Cutter 4,00x50mm

- Solid Carbide

- Standard Cutter

- 4,00 x 50 mm

- 9 available tip sizes

Standard Cutter 4,00x110mm

- Solid Carbide

- Standard Cutter

- 4,00 x 110 mm

- 9 available tip sizes

Standard Cutter 4,00x165mm

- Solid Carbide

- Standard Cutter

- 4,00 x 165 mm

- 9 available tip sizes

Standard Cutter 4,36x165mm

- Solid Carbide

- Standard Cutter

- 4,36 x 165 mm

- 9 available tip sizes

Standard Cutter 4,36x185mm

- Solid Carbide

- Standard Cutter

- 4,36 x 185 mm

- 9 available tip sizes

Standard Cutter 6,00x50mm

- Solid Carbide

- Standard Cutter

- 6,00 x 50 mm

- 9 available tip sizes

Standard Cutter 6,35x165mm

- Solid Carbide

- Standard Cutter

- 6,35 x 165 mm

- 9 available tip sizes

Quarter-Round Cutter 3,17x115mm

- Solid Carbide

- Quarter-Round Cutter

- 3,17 x 115 mm

- 9 available tip sizes

Quarter-Round Cutter 4,36x165mm

- Solid Carbide

- Quarter-Round Cutter

- 4,36 x 165 mm

- 9 available tip sizes

HSS-Cutter 3,17x115mm

- High Speed Steel Engraving Cutters

- 3,17 x 115 mm

- 9 available tip sizes

Engraving Cutters: Tools for processing Engraving Material

Engraving cutters are special tools that are mainly used for processing and engraving various materials. These tools are characterised by their ability to create highly precise and detailed engravings. The engraving graver is a traditional, manually guided tool that is mainly used in hand engraving.

A key feature of engraving cutters is their composition. They are made of high-strength materials such as solid carbide or alloyed tool steel (HSS), which stands for ‘High Speed Steel’, or are diamond-coated, which gives them extreme durability and sharpness. These properties are particularly important for machining hard materials such as metals, glass or stone without the milling cutter wearing out quickly or losing its sharpness. Engraving cutters are used in computer-controlled machines, known as CNC milling machines, or hand-held pantographs.

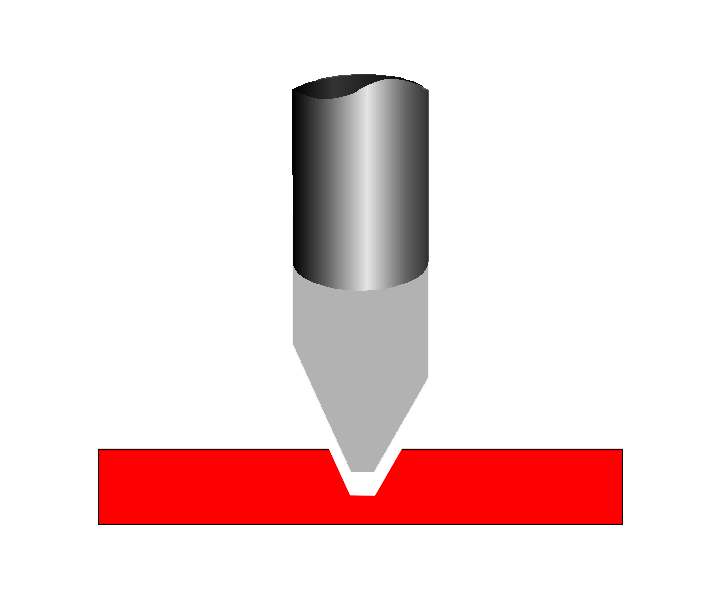

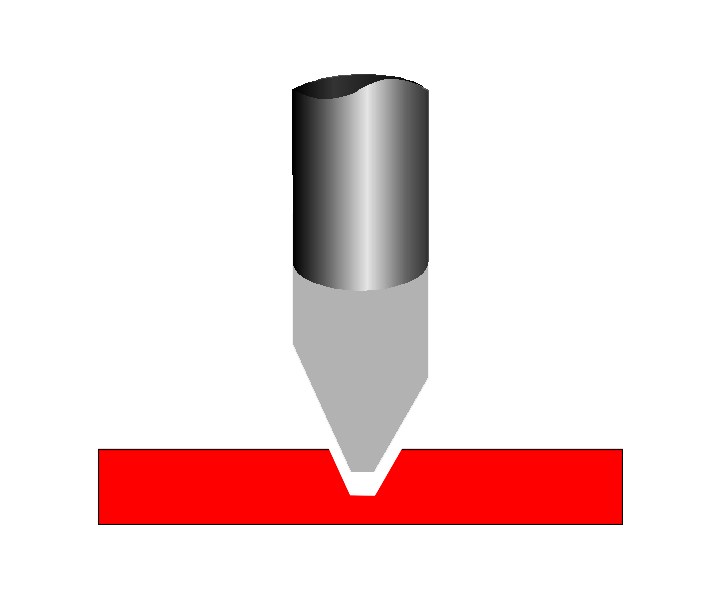

Our large range of milling cutters includes a variety of specialised tools that are used in various industrial applications. Standard cutters can be used universally and are suitable for a wide range of machining processes. They are often used in metalworking to perform precise cuts and surface machining.

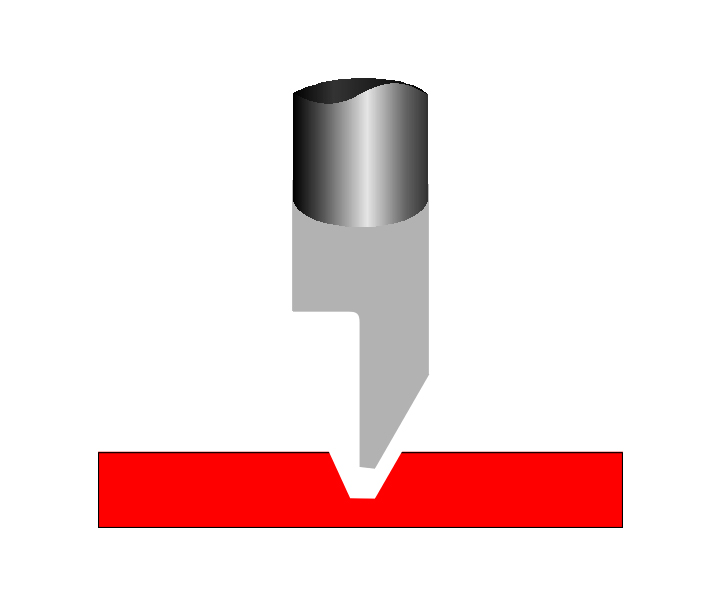

Quarter-Round Cutters are specialised tools that are characterised by their ability to create complex and precise patterns. These cutters are particularly useful when it comes to cutting detailed engravings in hard materials. HSS milling cutters, made from high-speed steel, offer excellent wear resistance and durability, making them ideal for demanding cutting and milling tasks.

End Mils, with two flutes, enable the milling of deep and narrow grooves thanks to their slim shape. These milling cutters are particularly effective when machining complicated workpiece geometries. Parallel milling cutters are versatile tools that are suitable for milling flat surfaces and cutting grooves.

Dovetail cutters are specially designed for the production of complex and precise shapes. They are able to produce different profile shapes in a single operation, which significantly increases efficiency and accuracy in production. Wide-cut cutters offer a high material removal rate thanks to their larger cutting surface and are ideal for fast processing of large surfaces.

Bevel cutters are specially designed to mill bevelled surfaces and edges. They are able to produce clean and even facets, which is particularly important in the jewellery and decoration industry. Spiral milling cutters, on the other hand, are optimised for machining metals and other hard materials thanks to their spiral-shaped cutting edges. These milling cutters offer improved chip removal and reduce heat generation during the milling process.

1 Flute Router-Mils, which are generally used for high-precision applications, are ideal for milling plastics and soft metals. Thanks to their special design, they enable precise control and clean cuts, making them an indispensable tool in precision mechanics and modelling.

To summarise, the extensive range of milling cutters offers the right tool for every specific requirement. From machining hard metals to fine engravings in soft materials, the variety and specialisation of the milling cutters ensure that the optimum tool is available for every task in order to maximise precision, efficiency and quality.