CerMark ULTRA Spray Can, 340g

- CerMark ULTRA Spray Can

- Black Laser Marking

- Stone, Brick and Slate Marking

- Tile and Glass Marking

- For Many Metals

- Easy Parameter Setup

- No Spray Nozzle Clogging

- Contents 340 g

CerMark ULTRA Spray Can, 56g

- CerMark ULTRA Spray Can

- Black Laser Marking

- Stone, Brick and Slate Marking

- Tile and Glass Marking

- For Many Metals

- Easy Parameter Setup

- No Spray Nozzle Clogging

- Contents 56 g

CerMark ULTRA, 100g

- CerMark ULTRA Concentrate

- Black Laser Marking

- Stone, Brick and Slate Marking

- Tile and Glass Marking

- For Many Metals

- Easy Parameter Setup

- Contents 100 g

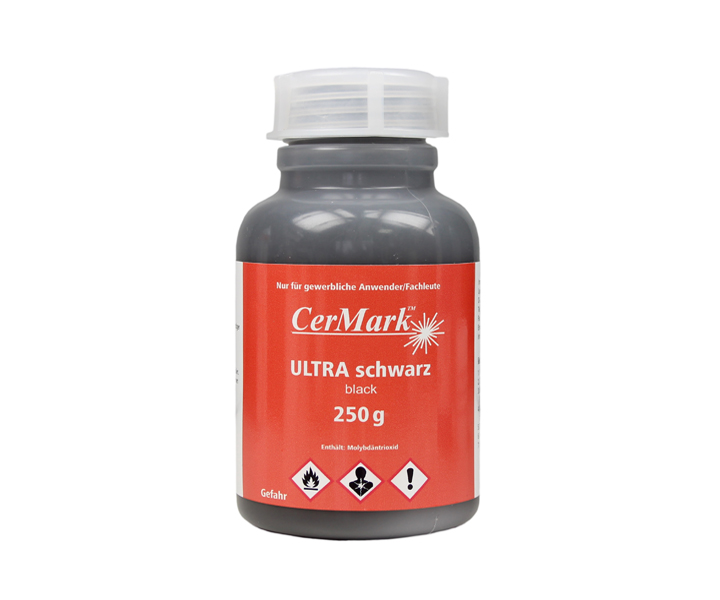

CerMark ULTRA, 250g

- CerMark ULTRA Concentrate

- Black Laser Marking

- Stone, Brick and Slate Marking

- Tile and Glass Marking

- For Many Metals

- Easy Parameter Setup

- Contents 250 g

CerMark ULTRA, 500g

- CerMark ULTRA Concentrate

- Black Laser Marking

- Stone, Brick and Slate Marking

- Tile and Glass Marking

- For Many Metals

- Easy Parameter Setup

- Contents 500 g

CerMark ULTRA: Laser marking of Metals with high contrast

CerMark ULTRA products have been specially developed to enable high-contrast and permanent laser marking on metals. These products are particularly effective when marking stainless steel, where they create deep black permanent markings. CerMark ULTRA is ideal for industrial applications where durability and legibility are critical.

CerMark ULTRA products are applied in several steps. Firstly, the metal surface to be labelled is thoroughly cleaned to ensure that no impurities impair the adhesion of the coating. The CerMark ULTRA coating is then applied. This can be done using one of the various packaging options: 100g, 250g or 500g bottles as well as a convenient 340g ready-to-use spray bottle. The concentrates in the bottle must be diluted according to the instructions before application. The coating is applied evenly to the surface and must dry completely before the laser process begins.

During laser engraving, the coating is heated, which leads to a chemical reaction that creates the permanent and high-contrast marking. On stainless steel in particular, this results in deep black markings that are characterised by their excellent legibility and durability. After the engraving process, the excess coating is simply washed off, leaving only the desired marking visible.